Two global "firsts"!Yizheng chemical fiber native polyester hollow leading the industry

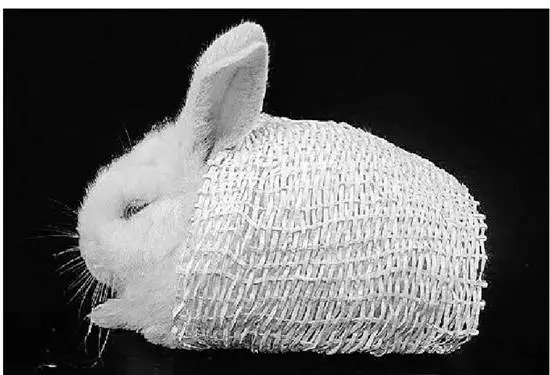

Two global "firsts"!Yizheng chemical fiber native polyester hollow leading the industry Recently, Sinopec Yizheng Chemical Fiber has successfully put into operation a special production line of native polyester hollow fiber with an annual output of 25,000 tons in the project of melt direct spinning environmental friendly staple fiber with an annual output of 200,000 tons, which helps Yizheng Chemical Fiber's native polyester hollow fiber business to take the lead in the industry and continue to maintain the two "No. 1" in the world with the most complete varieties and the largest output. Polyester hollow fiber is also called hollow fiber, a diameter of less than a human hair one over ten polyester hollow fiber, fiber can be seen under a microscope the longitudinal surface is smooth, transverse section pattern with eccentric circle holes, asymmetric structure with permanent three-dimensional crimp form of fibers, forming excellent fleeciness resilience, contained in the round hole is not the air flow, and have heat preservation effect. In addition to single hole, there are four holes, seven holes and other porous hollow fiber. Polyester hollow fiber has the characteristics of fluffiness, resilience, warmth preservation, good antibacterial and mildew resistance and light weight. It is widely used in many fields such as high-grade bedding and cold-proof clothing. Yizheng Chemical Fiber is a pioneer in the domestic R&D of polyester hollow fiber production. In 1990, the annual production line of 4,000 tons of polyester hollow fiber was introduced and put into operation, which opened the curtain on the domestic production of polyester hollow fiber.In 1994, through digestion, attraction and re-innovation, the company built the largest domestic polyester hollow fiber production line, and has won many awards such as the second prize for national scientific and technological progress.After many years of product and market development, yizheng chemical fiber polyester hollow fiber research and development corporation produced four holes, seven holes, feather, silk cotton, pearl cotton, flame retardant, antibacterial 11 categories of more than 50 brands such as hollow polyester series products, product quality through Swiss ecological textile standard argument, four holes, seven holes, the warm velvet, antibacterial, flame retardant, thermal, and other varieties to fill the domestic blank.In 2019, Yizheng Chemical Fiber produces 100,000 tons of raw polyester hollow fiber, accounting for 20% of the domestic raw polyester hollow fiber, becoming the world's most complete and largest raw hollow fiber production base.Yizheng chemical fiber through a number of domestic well-known brand home textile enterprises strong alliance, occupy the "China good core" half of the country. Yizheng chemical fiber corporation native polyester hollow fiber can be used in the hospital bed, mattress, pillow core, etc., to fight COVID - 19 outbreak since their products if necessa...

Feb 01, 2021

View More

![[Industry] Textile and garment export will grow by 9.6% in 2020.](/uploadfile/news/c31b87869b335ae07025edbb8d0425a3.jpg)